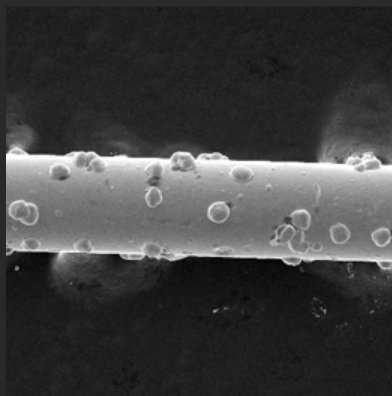

Ultra Thin Tungsten Wire

Tungsten is one of the so-called refractory metals, along with molybdenum, niobium, rhenium, and tantalum. These materials are known primarily for their high melting points. After pressing, sintering, swaging, drawing, and annealing process, we get fine tungsten wire from tungsten powder.

Product Types:

We provide fine tungsten wire from 0.005mm to 2.5mm, regular types as below:

Diameter | Colors |

0.015mm | Black |

White | |

0.020mm | Black |

White | |

0.025mm | Black |

White | |

0.030mm | Black |

White | |

0.035mm | Black |

White | |

0.040mm | Black |

White | |

0.045mm | Black |

White | |

0.05mm | Black |

White |

The Highest Melting Point

High tensile Strength and Extreme Hardness

The Lowest Vapor Pressure of All Metal

Resistance to Oxidation and Creep

Good Electrical and Thermal Conductivity

Extremely Fine, Soft Monofilament

Super Advantages

Tungsten has long served industry based on its unique properties — sometimes because of just one unique property, sometimes based on a combination.

Application

Power supplies, electrical parts

Electrodes for various incandescent, fluorescent and halogen lamp filaments and HID lamps, TIG electrodes, etc.

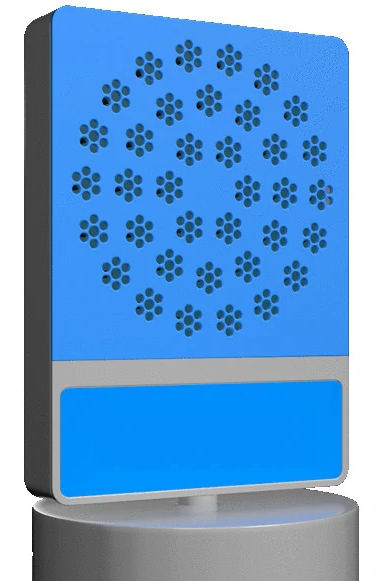

Electrostatic adsorption

Fume cleaners, electrostatic precipitators, air purifiers, printers, photocopiers, integrators

Medical products

Ultra-fine tungsten wires have become the material of choice for the production of micromechanical filaments used in modern surgical robots.

Textiles, weaving

The tungsten wire can be very thin but strong, which ensures that the glove is cut and abrasion resistant and at the same time comfortable to wear.

High temperature heat generators and h structural components

Tungsten wire can be used to build heating coils and vacuum heating parts, using its excellent thermal properties to radiate large

Photovoltaic diamond wire

Tungsten wire has high strength, can be processed very fine and has good fatigue resistance, reusable and long-lasting, forming an alternative to diamond wire busbars for cutting silicon wafers.